Our Capabilities

Plasma Cutter

Some applications require thicker forms of sheet metal due to the various structural advantages it provides. Cutting thicker material presents a number of obstacles that reach beyond the capabilities of typical laser and other forms of metal cutting in terms of cutting efficiency, tooling setup, and cost. Plasma cutting is the most cost-effective process used on thicker metals to gain clean cuts without a custom tooling setup.

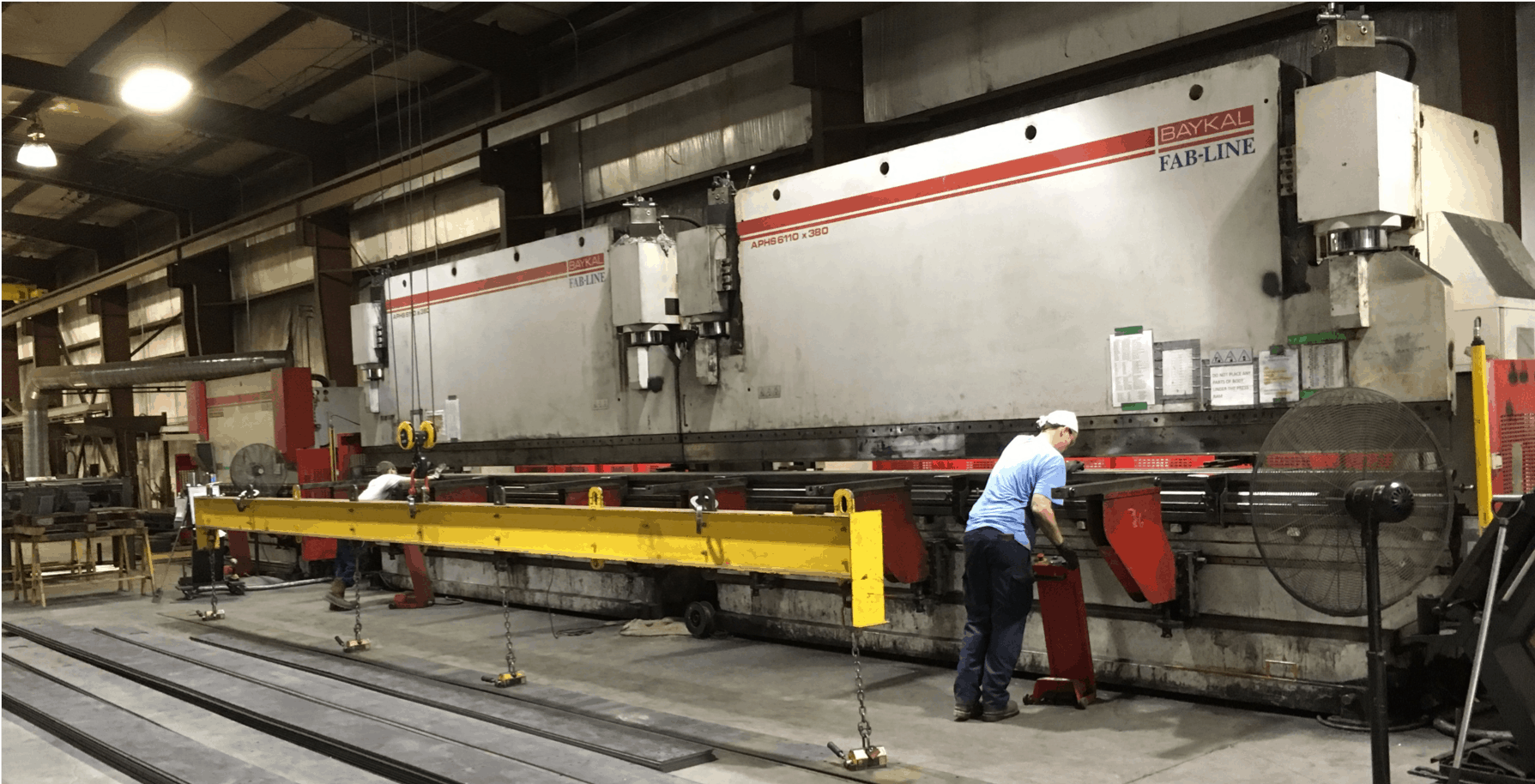

Press Brake Services

Metal fabrication often requires carefully controlled pressure to bend materials precisely without snapping or unexpected curving. Hydraulic and manual press brakes bend metal by precisely applying force to create accurate pressed folds and edges without marking the metal.

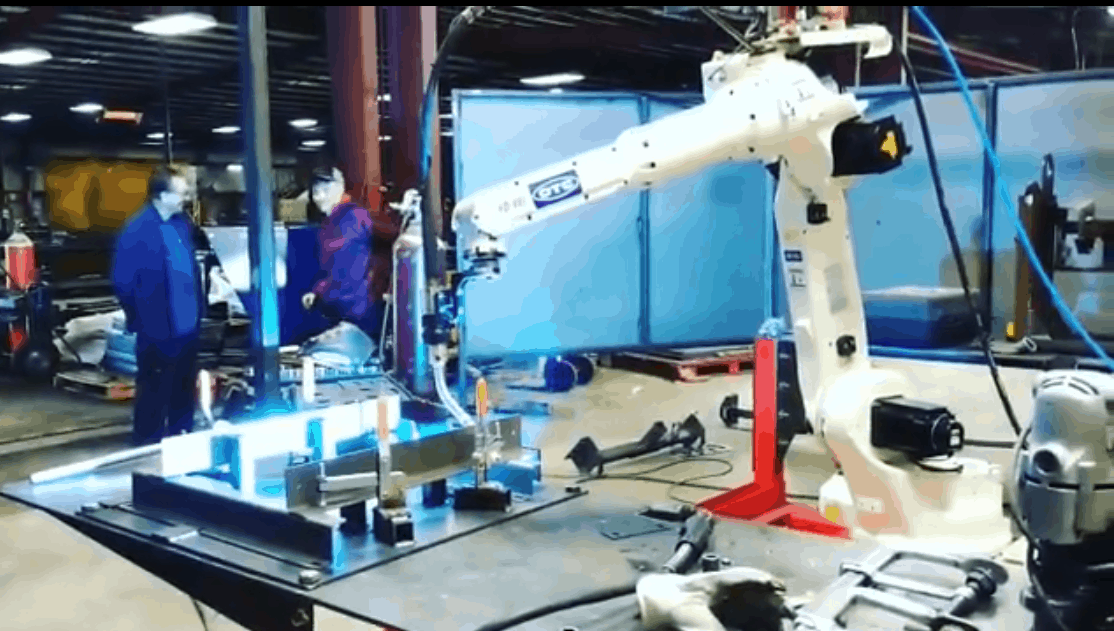

Welding & Fabrication

Welding is a type of fabrication process that forms parts and structures by using high heat to melt and join metal materials. The technique often goes hand-in-hand with other manufacturing processes such as sheet metal fabrication, as both employ similar operations (such as assembly and bending) to achieve their end products.

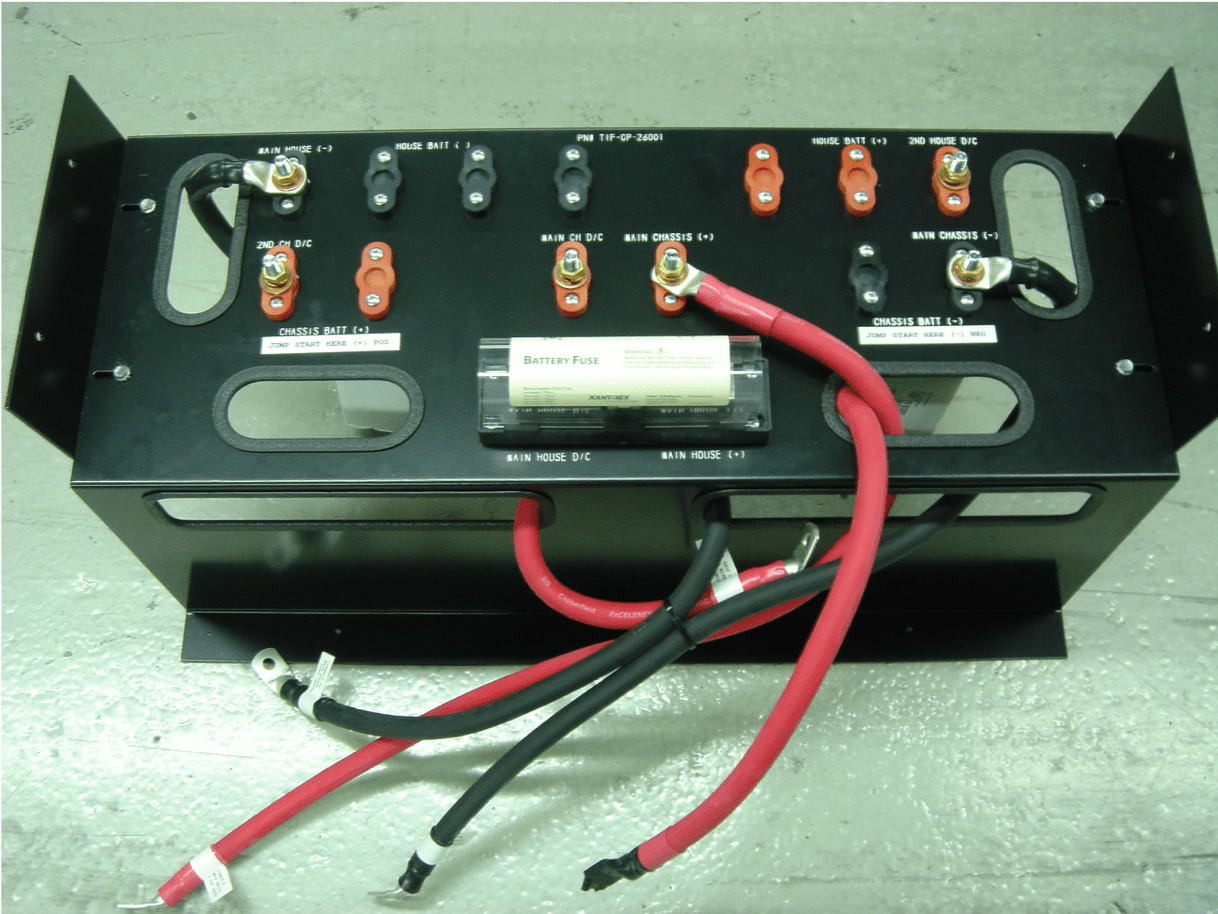

Mechanical Assemblies

Electromechanical assemblies employ a combination of electrical and mechanical parts and components to perform various operations, including power generation, systems control, and executing power-enhanced mechanical tasks. Designing and assembling electromechanical parts. devices involve a number of stages, including in-housepart procurement, engineering, and production operations, as well as performance and quality testing. With the development of new electrical technology, many of the functions that were, at one time, commonly associated with these electromechanical devices are now performed by integrated electronic circuits.

Injection Molding Thermosplastic

Thermoplastic injection molding (TIM) is a fabrication process that injects melted thermoplastic material into molds to create duplicatable functional parts and components with high levels of accuracy in large quantities.

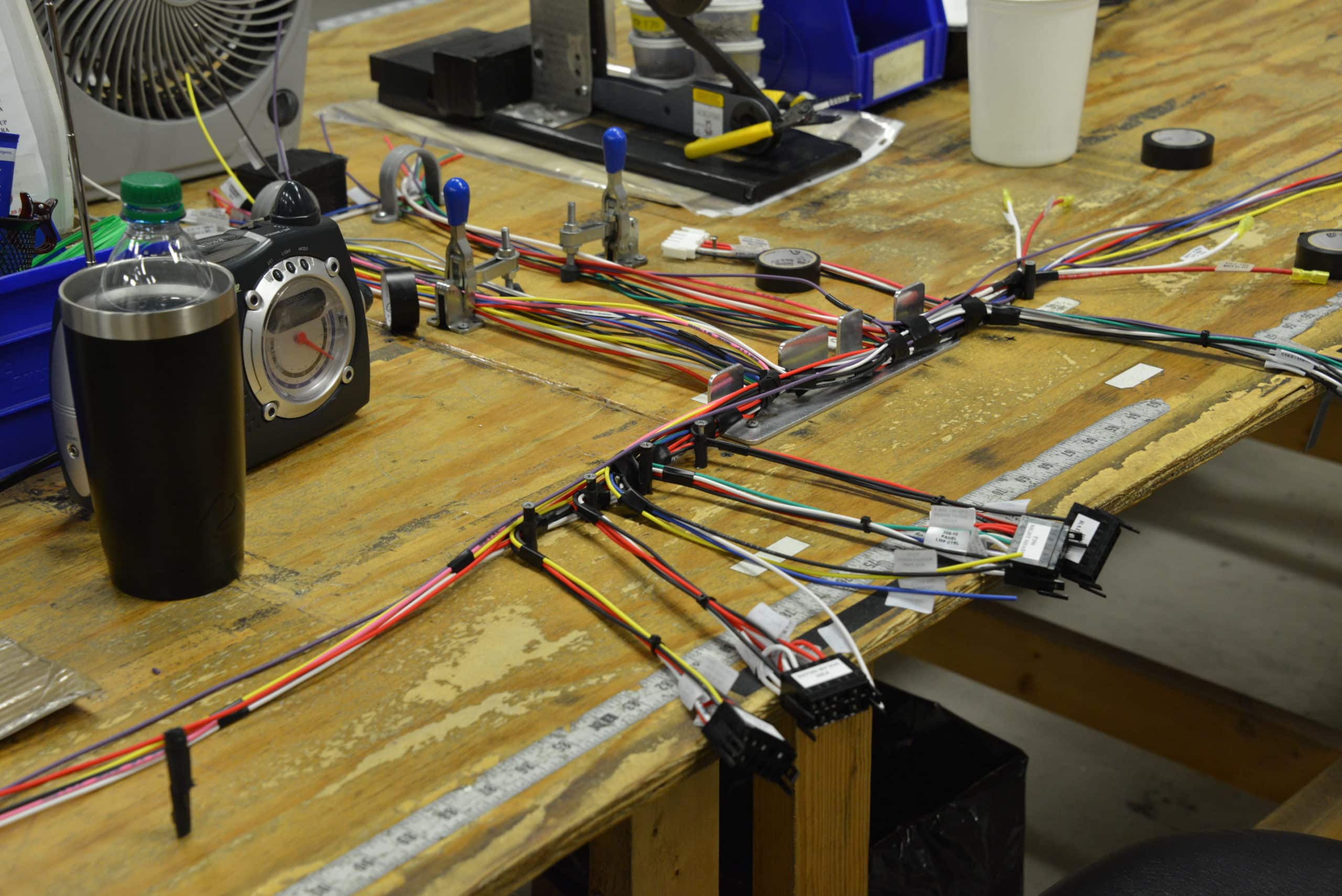

Wire Harness & Cable Assemblies

Wire harnesses are intended to protect wires from their environments. They’re generally made of thermoset or thermoplastic materials and form external sheaths, which are then used to cover cables and wires. Using wire harnesses to bundle these wires and cables together is a common practice in many industries. This way, electrical contractors and engineers have increased control over the organization of their wiring systems, as well as additional protection from current flow.

Kitting, Packaging & Order Fulfillment

Kitting is a common step in industrial and fulfillment processes. It refers to the process of assembling individual items together into one package that is For example, distribution warehouses have kitting procedures to pack c orders for shipment.