Plasma Cutter

Some applications require thicker forms different thickness of sheet metal due to the various structural advantages it provides requirments. Cutting thicker such a rage of material thickness presents a number of obstacles that reach beyond the capabilities of typical laser and other forms of metal cutting in terms of cutting efficiency, tooling setup, and cost. Plasma cutting is the most cost-effective process used on thicker this range of metals to gain clean cuts without a custom tooling setup.

Plasma cutting works as follows:

- The plasma cutting process uses a high-temperature, high-velocity stream of ionized gas in the form of a plasma stream.

- A copper nozzle contains and directs an arc created by the enclosed electrode in the cutting head of the unit.

- This creates a transfer arc in the conductive material being cut and produces a greater capacity for cutting through thicker sheets of metal than attempting the same with regular laser cutting.

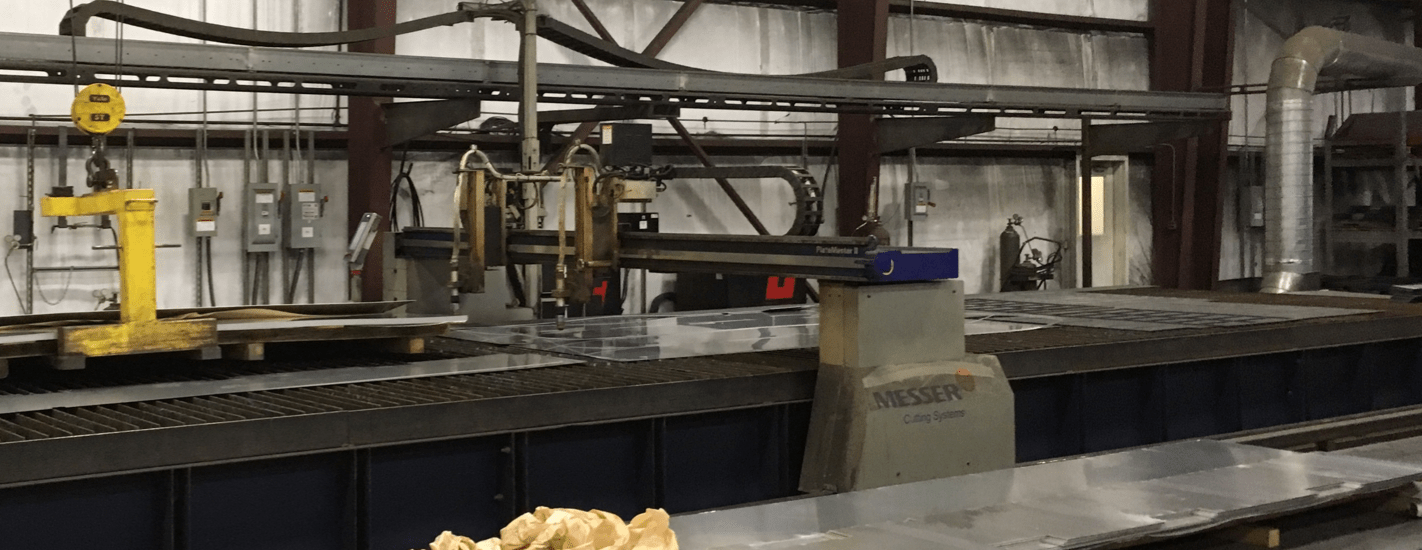

Machine List

We have multiple plasma cutters that grant us the capabilities to meet a wide range of cutting needs. Included among our machines are a CNC Controlled Messer 260XD Single Head Plasma Table, and a CNC Controlled Messer 260XD Dual Head Plasma Table. The features of both of these tables include:

- 45′ x 12′ table dimensions, allowing us to cut material up to 40 feet in length

- Cut materials with thicknesses range from .062 up to 1.5″

- Capacity for cutting angles or straight cuts

- Capable of cutting steel, stainless steel, aluminum and other conductive metals

Common Industries and Applications

The combination of our expertise and equipment allows us to serve a broad range of clients with varying needs. Heavier, thicker sheet metal has certain structural properties that provide strength and durability to a variety of industrial applications. Cutting thicker material using common laser cutting and other forms of sheet metal cutting provides challenges that can easily be overcome using a plasma cutter.

For example, we often use our plasma cutting services to support clients in the mobile home manufacturing and construction industries for parts such as:

- Frame rail cross members (motor homes)

- Subpanel walls (motor homes)

- Electromechanical panels (construction)

- Structural trusses (construction)

- Plates and panels of all shapes and sizes with holes and slots as required

- Blanks for structural forms, brackets and braces

Plasma Cutting from Tri-Cities Manufacturing

The team at TCM uses state-of-the-art equipment supported by stringent quality assurance and process control, which allows us to provide high-quality plasma cutting services. Our customer service team also provides Just-in-Time delivery using overnight freight lines or our own vehicles to ensure your order is delivered when you need it.

Contact us for more information about our plasma cutting capabilities or any of our other services.